Introduction

Power diodes are essential building blocks in the domain of power electronics. They serve as unidirectional switches that allow current flow in one direction while blocking it in the other. Their ability to handle high voltage and current levels makes them indispensable in various applications like power rectification, voltage regulation, protection circuits, and more.

In this comprehensive guide, we’ll explore all the major types of power diodes, their underlying physics, materials used (Silicon and Silicon Carbide), real-world applications, performance characteristics, and why they remain critical components in modern and next-generation electronic systems.

Introduction

Power diodes are essential building blocks in the domain of power electronics. They serve as unidirectional switches that allow current flow in one direction while blocking it in the other. Their ability to handle high voltage and current levels makes them indispensable in various applications like power rectification, voltage regulation, protection circuits, and more.

In this comprehensive guide, we’ll explore all the major types of power diodes, their underlying physics, materials used (Silicon and Silicon Carbide), real-world applications, performance characteristics, and why they remain critical components in modern and next-generation electronic systems.

What is a Power Diode?

A power diode is a two-terminal electronic device constructed from semiconductor material and is designed to convert alternating current (AC) to direct current (DC), also known as rectification. Unlike signal diodes, power diodes are engineered for high-current and high-voltage applications.

Basic Operating Principle

The diode allows current to flow when the anode is at a higher potential than the cathode (forward bias), and blocks current when the polarity is reversed (reverse bias). It is this simple behavior that makes the diode the fundamental switching element in many power electronic circuits.

Symbol and Construction

- Symbol: Anode →|← Cathode

- Junction: Based on either a PN junction or a Schottky metal-semiconductor contact

- Package Types: TO-220, TO-247, DO-41, surface mount (SMT) packages

Classification of Power Diodes

Power diodes are classified based on:

1. Material Used:

- Silicon (Si) — traditional, lower cost, well-established

- Silicon Carbide (SiC) — emerging, high-temperature and high-frequency capable

2. Structural Type:

- PIN Diode

- Schottky Diode

- JBS (Junction Barrier Schottky) Diode

3. Application Speed:

- General-purpose Diodes — slow recovery, high power

- Fast Recovery Diodes — moderate speed and power

- Ultra-Fast Recovery Diodes — highest speed, lower power

1. PIN Diode (Silicon-Based)

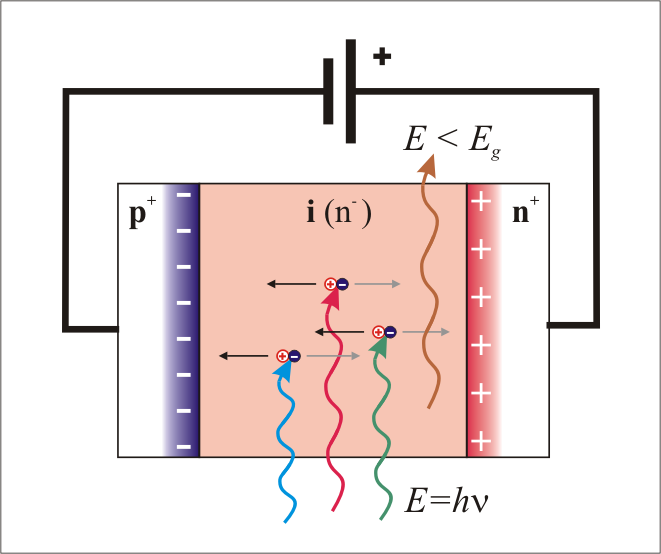

Structure and Working

The PIN diode features three layers:

- P+ (heavily doped positive region)

- I (intrinsic layer)

- N+ (heavily doped negative region)

The intrinsic layer increases the depletion region, which enhances the device’s voltage-blocking ability. Under forward bias, this layer becomes conductive due to carrier injection. Under reverse bias, it sustains the electric field and blocks current.

Electrical Characteristics

- Forward Voltage Drop: ~0.7V to 1.1V

- Reverse Recovery Time: 3–50 μs (depends on design)

- Voltage Rating: Up to several kV

- Current Rating: Up to several kA

Applications

- Line-frequency rectifiers

- High-voltage DC (HVDC) transmission systems

- Industrial motor control systems

- DC power supplies for high-current applications

Advantages

- Excellent high-voltage capability

- Low reverse leakage current

- Robust thermal handling

Limitations

- Relatively slow switching speeds

- Higher forward voltage drop compared to Schottky

2. Schottky Diode (Silicon and SiC-Based)

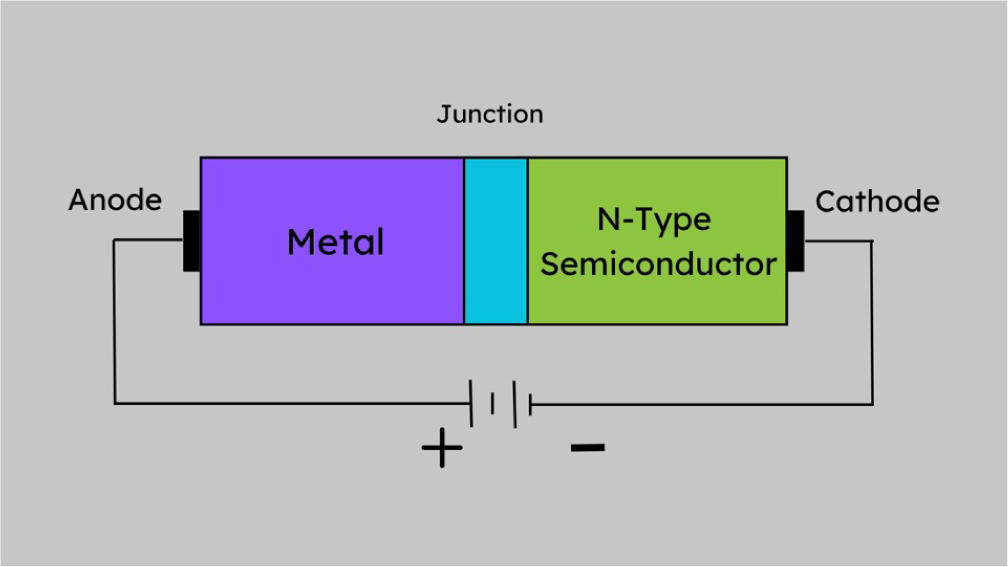

Structure and Working

Unlike traditional PN junction diodes, Schottky diodes use a metal-semiconductor junction (typically aluminum or platinum with N-type silicon). This gives rise to:

- Low barrier potential (~0.3V in Si, ~0.7V in SiC)

- Fast majority-carrier operation (no minority-carrier storage)

Electrical Characteristics

- Forward Voltage Drop: ~0.2V (Si), ~0.7V (SiC)

- Reverse Recovery Time: Practically zero

- Voltage Rating: 20V–200V (Si), up to 1.2kV (SiC)

- Leakage Current: Higher than PIN, especially in Si

Applications

- High-frequency SMPS (Switched Mode Power Supplies)

- High-speed digital and RF circuits

- Solar microinverters

- Electric vehicle (EV) auxiliary circuits

Advantages

- Ultra-fast switching speeds

- High efficiency (low conduction loss)

- Simple to implement in fast-switching converters

Limitations

- Higher reverse leakage (especially Si)

- Lower reverse voltage capability (except SiC variants)

- Thermal limitations in Si-based devices

Why SiC Schottky is Better

- Much lower reverse leakage current

- Superior high-temperature and high-voltage operation

- Ideal for wide-bandgap applications

3. JBS (Junction Barrier Schottky) Diode (SiC-Based)

Structure and Hybrid Nature

The JBS diode combines:

- A Schottky junction for fast switching

- A PN junction for improved reverse blocking

This hybrid configuration uses P+ guard rings embedded within an N-drift region to suppress leakage and enhance voltage blocking.

Electrical Characteristics

- Forward Voltage Drop: ~0.4–0.6V

- Voltage Ratings: 600V–1700V (commonly)

- Leakage Current: Very low

- Reverse Recovery: Very fast (but not zero)

Applications

- On-board chargers in EVs

- Industrial drives and motor control

- Photovoltaic inverters

- PFC stages in power supplies

Advantages

- Combines speed of Schottky and robustness of PIN

- Excellent surge and thermal behavior

Limitations

- Slightly higher cost

- Forward drop is higher than pure Schottky

Additional Diode Types

Fast Recovery Diodes

- Used in induction heating and UPS systems

- Recovery time in tens of nanoseconds

Avalanche Diodes (TVS)

- Provide protection from voltage transients

- Used in ESD and surge protection applications

Comparison Table: PIN vs Schottky vs JBS

| Feature | PIN Diode (Si) | Schottky (Si & SiC) | JBS (SiC) |

|---|---|---|---|

| Reverse Voltage | High (up to kV) | Low (Si), High (SiC) | High (600V–1700V) |

| Forward Voltage Drop | 0.7–1.1V | 0.2–0.4V (Si), ~0.7V (SiC) | 0.4–0.6V |

| Switching Speed | Slow | Ultra-fast | Fast |

| Leakage Current | Very Low | High (Si), Low (SiC) | Very Low |

| Surge Current Capability | Excellent | Moderate | Excellent |

| Application Examples | Rectifiers, HVDC | SMPS, RF, EV DC-DC | EVs, PFC, Solar Inverters |

2025 Trends: What’s New in Power Diodes?

- SiC is replacing Si in applications where efficiency and thermal reliability are priorities

- Wide Bandgap (WBG) devices like SiC Schottky and JBS are now mainstream in EVs and renewable systems

- Integration in modules: Many manufacturers are offering integrated diode-transistor modules for compact design

Case Study: Tesla’s use of SiC diodes in Model 3’s inverter improved efficiency by 10%, enabling longer driving range and reducing cooling needs.

Real-World Applications in Action

| Application | Diode Type Used | Reason |

| Tesla EV Inverter | SiC Schottky | Efficiency, thermal stability |

| Data Center Power Supply | SiC JBS | Fast recovery, low power loss |

| Solar Inverter | SiC JBS | Low leakage, reverse blocking, compact design |

| Industrial UPS | Fast Recovery PIN | High surge, robustness |

| SMPS for Telecom | Si Schottky | Low cost, fast switching |

FAQs

Q1: What is the difference between a PIN and a Schottky diode?

A PIN diode uses a PN junction with an intrinsic layer for high voltage blocking, while a Schottky diode uses a metal-semiconductor junction for faster switching and lower forward voltage.

Q2: When should I choose a JBS diode?

When you need both high-speed switching and strong reverse blocking, such as in PFC circuits or EV drives.

Q3: Is SiC always better than Si?

Not always. Si is still cost-effective for low-power applications, but SiC is superior in high-power, high-frequency, and high-temperature environments.

Q4: What is reverse recovery time?

It’s the time taken by a diode to stop conducting after the polarity of voltage is reversed. A lower value means faster operation.

Q5: Can I use a Schottky diode in place of a standard diode?

Yes, if the voltage rating is sufficient and higher leakage is acceptable. For precision or protection circuits, this may not be ideal.

Conclusion

Power diodes may appear simple, but they are engineered with complex materials and structures to meet specific application needs. From the conventional PIN diodes used in rectifiers to cutting-edge SiC Schottky and JBS diodes powering electric vehicles and solar farms, each has its niche.

With the ongoing evolution of power electronics, SiC-based diodes are paving the way for more efficient, compact, and reliable power systems in the 21st century. Whether you’re designing a basic AC-DC converter or a high-end EV inverter, understanding power diode types will empower you to make the right choice.

Written by: https://top10electrical.com/

Reviewed: 2025

Primary Source: Power Electronics by Muhammad H. Rashid, Fourth Edition; Pearson